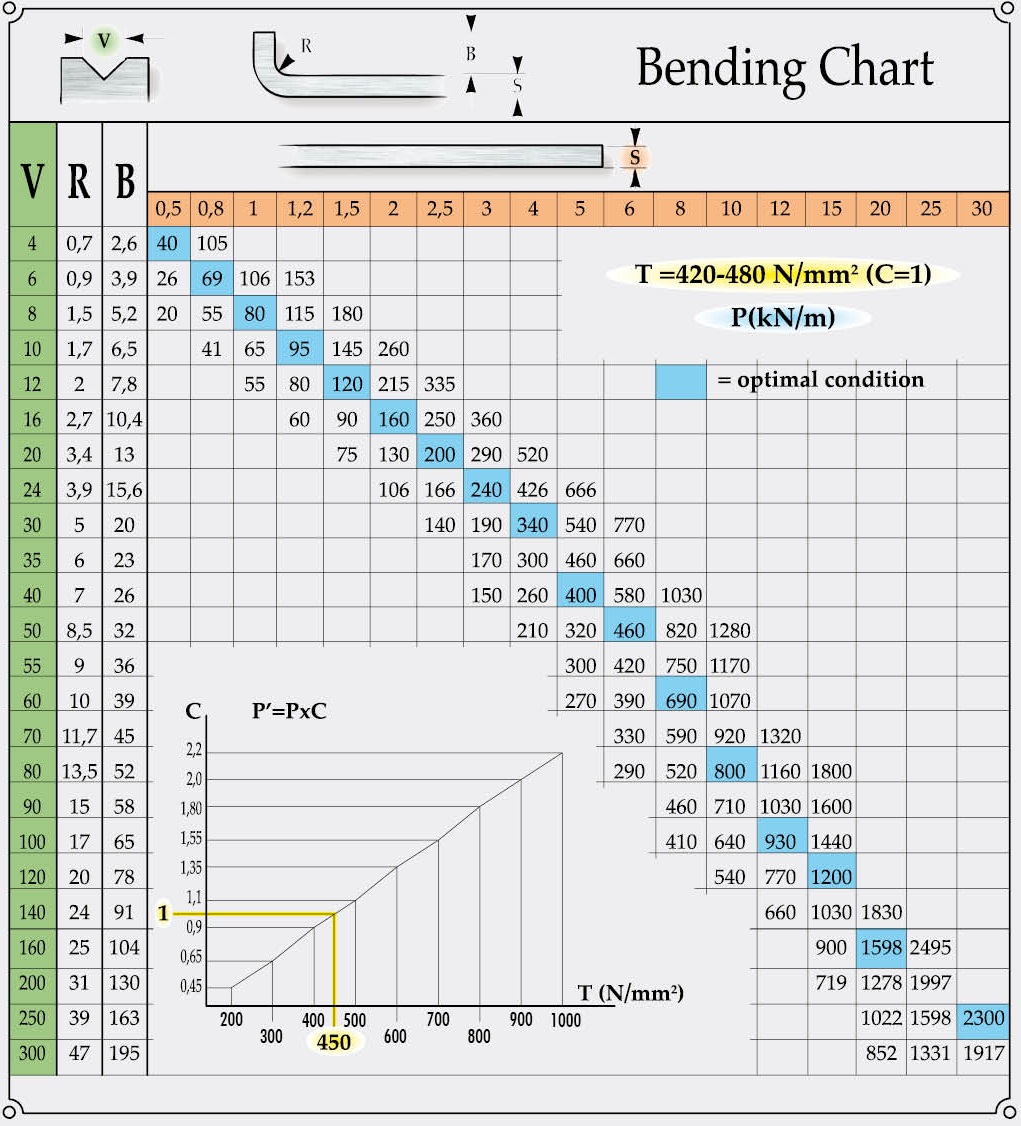

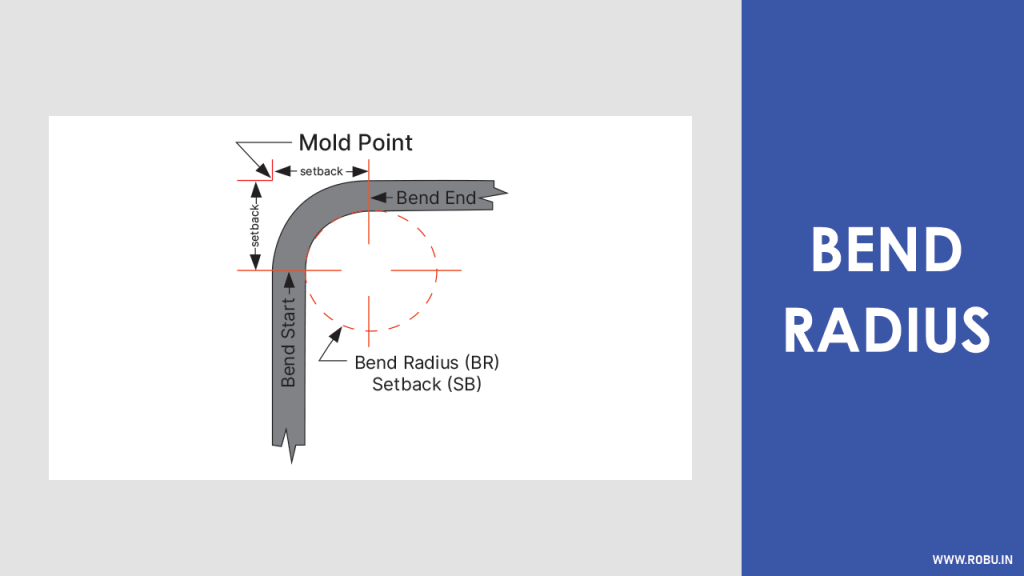

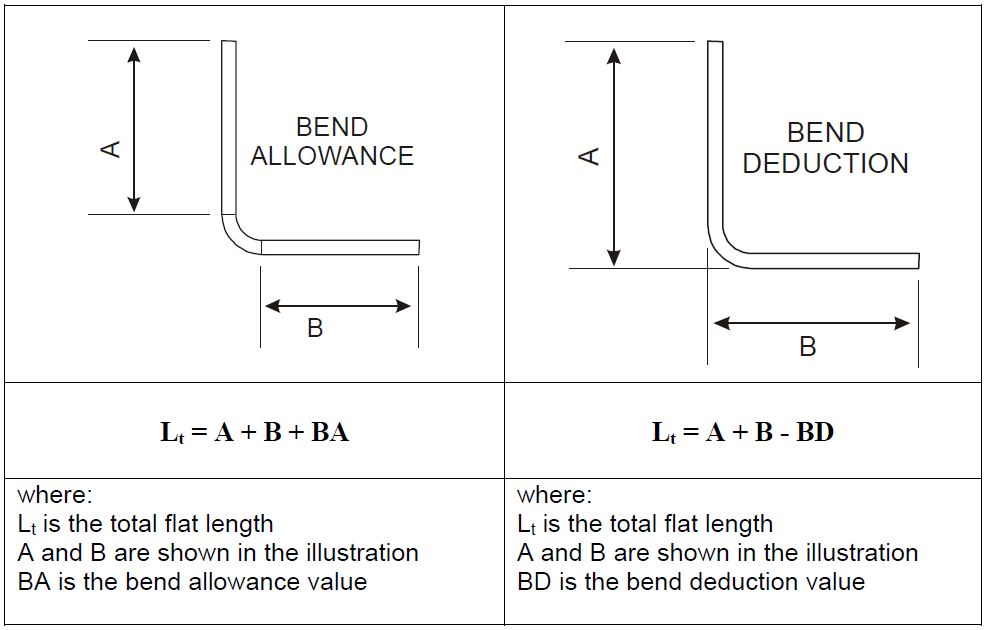

Sheet Metal Bend Radius - The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Minimum hole distance and minimum flange distance. Below is a table summarizing the. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. This radius is dependent on the material. We’ve broken down our minimum bend radii into two values: It is important because it helps determine the.

This radius is dependent on the material. Below is a table summarizing the. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Minimum hole distance and minimum flange distance. It is important because it helps determine the. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. We’ve broken down our minimum bend radii into two values:

The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. We’ve broken down our minimum bend radii into two values: The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. It is important because it helps determine the. This radius is dependent on the material. Minimum hole distance and minimum flange distance. Below is a table summarizing the.

Sheet Metal Inside Bend Radius Calculator at Joel Watts blog

The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. We’ve broken down our minimum bend radii into two values: Minimum hole distance and minimum flange distance. This radius is dependent on the material. It is important because it helps determine the.

Understanding Sheet Metal Bending Radius and Thickness

It is important because it helps determine the. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Below is a table summarizing the. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during.

Sheet Metal Thickness And Bend Radius at Michael Wannamaker blog

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. We’ve broken down our minimum bend radii into two values: It is important.

MS Sheet Metal Radius Bending, Bend Radius 3D at ₹ 15/kg in Ahmedabad

This radius is dependent on the material. Below is a table summarizing the. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. Minimum hole distance and minimum flange distance. It is important because it helps determine the.

Sheet Metal Bending Calculation With Example at Rita Skelley blog

The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. It is important because it helps determine the. We’ve broken down our minimum bend radii into.

Predicting an airformed sheet metal inside bend radius

The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. It is important because it helps determine the. Minimum hole distance and minimum flange distance. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

Minimum hole distance and minimum flange distance. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. This radius is dependent on the material. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material.

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts

Minimum hole distance and minimum flange distance. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. It is important because it helps determine the. This radius is dependent on the material. Below is a table summarizing the.

Minimum Bend Radius Reference Table For Sheet Metal Xometry Pro

It is important because it helps determine the. Minimum hole distance and minimum flange distance. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. We’ve broken down our minimum bend radii into two values: This radius is dependent on the material.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

This radius is dependent on the material. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. It is important because.

This Radius Is Dependent On The Material.

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Below is a table summarizing the. We’ve broken down our minimum bend radii into two values: Minimum hole distance and minimum flange distance.

The Sheet Metal Bending Radius Is A Critical Value In Sheet Metal Drawing That Can Be Difficult To Determine During The Actual Processing.

It is important because it helps determine the. The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation.